Friday, June 19, 2015

And they (OK, I) said it couldn't be done...

I promised you we'd be dealing with the Gehl (pronounced Gale) swather today and I did. The last time I ran it after installing new belts, it sounded like a rock crusher/auto wrecker and was making more metal shavings than hay. No bueno.

Today I broke out my tools and started taking things apart. I have to say I wasn't enthusiastic about being able to fix it, metal shavings are usually a sure sign of death around old equipment. Disassembling everything went relatively quick thanks to my air tools. If you don't have any, get some. Even cheap air tools are better than box wrenches and ratchets.

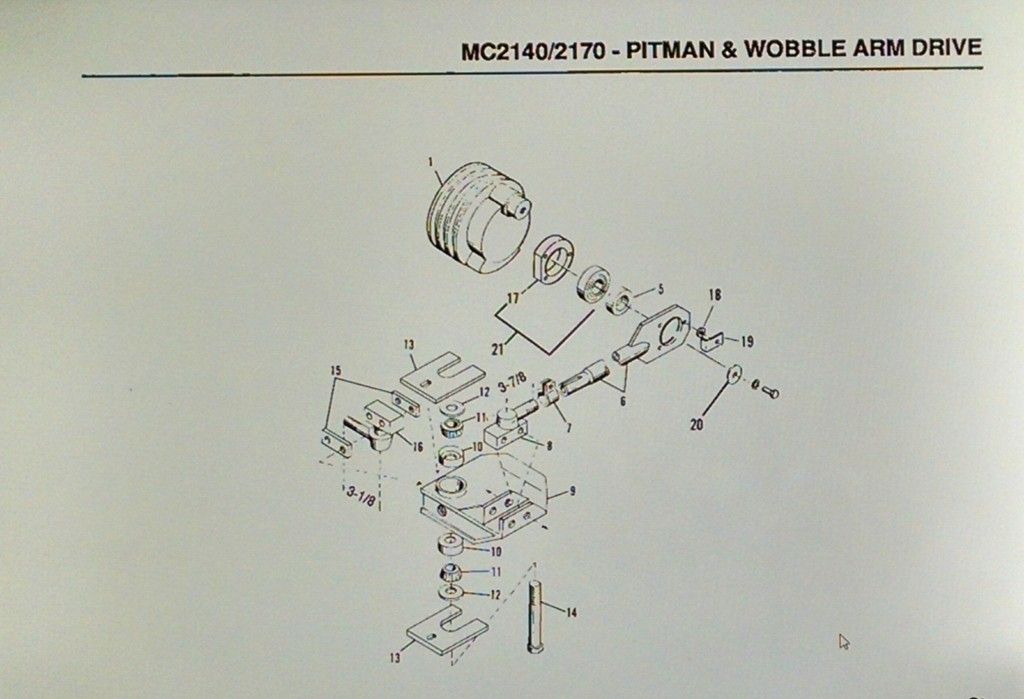

It didn't take long to see what the problem was. The large bolt that acts as an axle for the wobble arm (appropriately named) was stripped and flopping around. The loose bolt led to the bearings disintegrating. The cotter pin holding the stripped nut in place was grinding away as the bolt flopped around and leaving the metal shavings I saw.

I called the salvage yard I bought some parts from before and I guess they were going to make up for the bargain I got before. The guy wanted $80 + shipping for the bolt. F that.

Instead I took a trip to Bridgeport Automotive and rummaged through their stock. Lo and behold, not only did they have the right bolt, they had several hardness grades for me to choose from. I picked a Grade 10 and several other assorted nuts, carriage bolts and washers I needed. I was batting .1000!

Then came the stumbling block, the bearings. We measured with calipers but the bearings wouldn't slide past the threads. I bought the nuts and bolts then tried Purvis for the bearings. I hate going there because they are high as heck and I call the counter guy Marlboro Man. When I walked in the door it smelled like he'd smoked at least a pack today. (I know, Ex-smokers are the worst about complaining about smokers.) They had the same result, wouldn't slide past the threads, but Marlboro Man had already billed me for the bearings before he got them out. I took them anyway, went to B&R Machine Shop and had the bolt run on a lathe to smooth out any ridges. VOILA! The bearing slid right on!

Back to the South 40, a few sweat soaked minutes knocking out the old bearing races and installing new ones then reassembling the wobble arm and I was done. I cranked up the tractor and gave it a test run. It was MUCH quieter and no longer sounded and felt like it was going to fly apart at any second. I think the old girl has at least one more season of hay cutting left in her. I guess we'll find out tomorrow if it's dry enough, because I'm seriously behind schedule on cutting hay.

Next up, getting the round baler field ready!

Subscribe to:

Post Comments (Atom)

2 comments:

How's your grass fairing during our monsoon season?

It looks marvelous. I fertilized and weed killed in April before the rain started. Now it's a sea of green over a foot tall. Just waiting on the field to dry up enough to cut and bale. Maybe Sunday.

Post a Comment