When we last left South 40 Farms I was waiting on drive belts for my Gehl swather. They arrived this afternoon and I jumped righ to getting them reinstalled. I knew this was going to be tough, but I had no freaking idea.

I put the belts on then heaved the gearbox into position. It was 110% effort Coach, I swear! It was full effort for 20 minutes in the blazing sun and 0 wind. It wasn't cooperating at all. First my straw hat became saturated with sweat. Then it started to drip off the brim. When the drip turned to a steady stream I cried "calf rope" and headed for some cold lemonade and a/c.

It was time to call in reinforcements. BIL was out of town and I rely on him too much as it is. So I decided to call my good friend Sam and beg him to bail me out. Fortunately he was home and had just finished a project in his shop. He came over and I laid out the situation to him.

We fought and struggled for at least half an hour in the blazing sun (I really need to build an awning over the work area). Then Sam started thinking about removing more stuff to get the gearbox in place. I nixed that quick, because it came out in 1 piece, it WILL go back in the same way. During this period of alternative discussion, the rake drive belt was moved 'out of the way'. Stay tuned sports fans.

It's hot, the space is tight, nothing is cooperating and both of us are close to losing our temper when suddenly.... it slips right in place! I scramble to get one of the bolts in the shaft bearing so it can't slip. VOILA!

Except for the rake drive belt that got moved to the wrong side of the driveshaft. It has to go under, not over. We have to take it apart.

I called timeout and we headed for shade and Gatorade. As we cooled off and rehydrated Sam agreed there was no freaking way I was ever going to get that belt on by myself and whoever designed this piece of machinery need to be hung with a very itchy rope.

We took the bolt out of the shaft bearing and lowered the gearbox, moved the belt to run below the shaft then tried to lift it back again. To both our amazement, it slipped right into place somehow on the first try! I scrambled to find the carriage bolt. Where the &%$# is it? Sam's screaming "Put in the bolt! Put in the bolt!" I looking everywhere then I remember there are 2 more in the box I put all the nuts, bolts, ect in when I took things apart. I find a bolt, Get it in the hole, then scurry under the swather to get the nut on.

SUCCESS! It's all downhill from here!

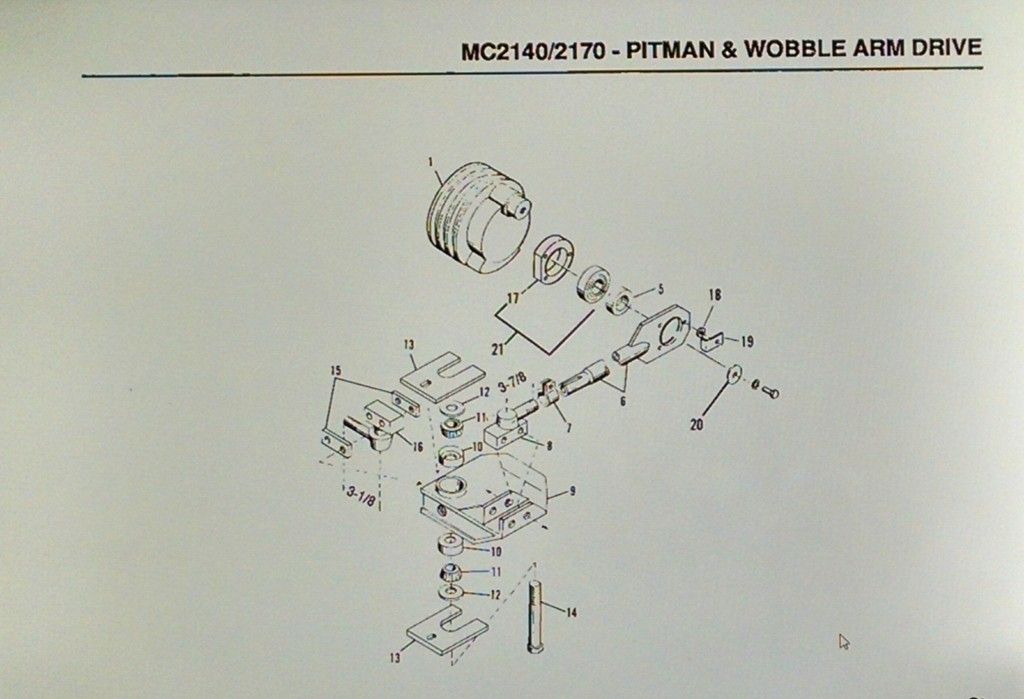

Replace the other 2 carriage bolts on the shaft bearing, the 4 bolts in the top of the gearbox, replace belt and chain tensioners, reconnect the Pitman drive and the main driveline. All that took about 10 minutes.

Let me tell you, Bud Light never tasted so good. I knew I put a fridge in the shop for a reason. Now I'm waiting on the dryer and expansion valve for my tractor a/c (C'mon FedEx, WTF?). I have a reman compressor I picked up from APE, but I'm not installing it until I get the rest of my parts. Then we see how long everything holds together.

Now if you'll excuse me I need some Motrin and herbal therapy for my aching back.